CENTRIFUGAL BOILER ISAV

|  |  |  |

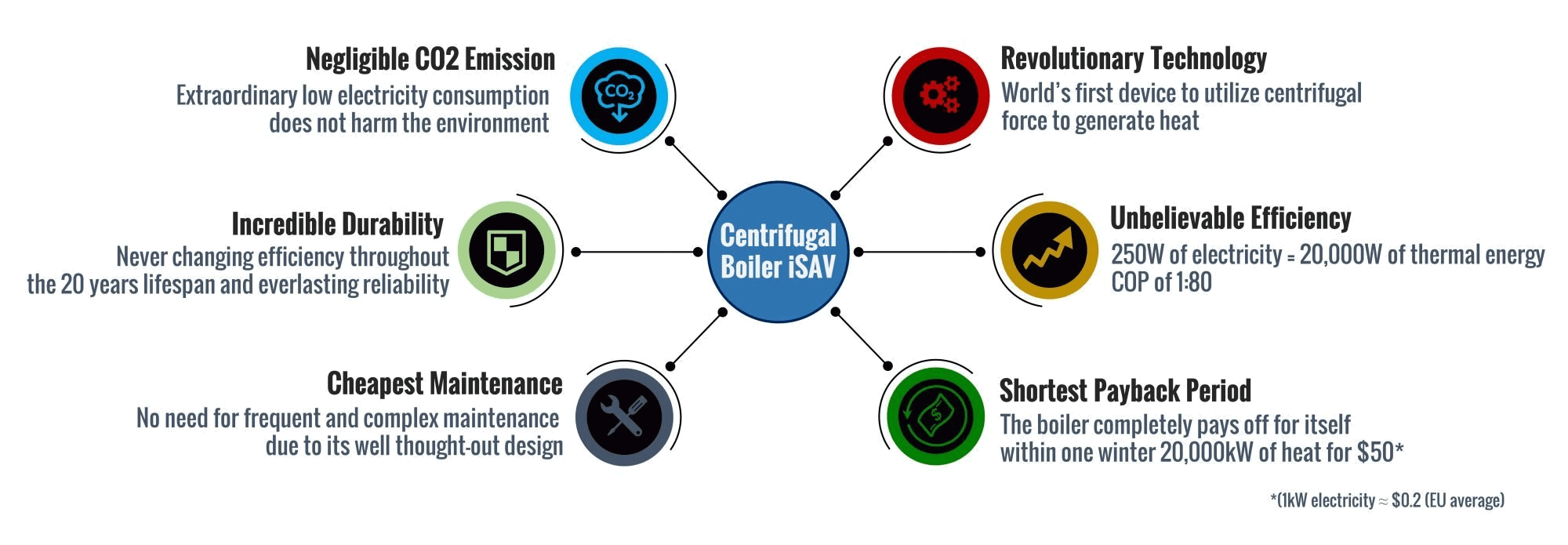

Infinity SAV achieved a result that allows to get up to 20 kW of thermal power from a power source of 200 W/h of electrical energy.

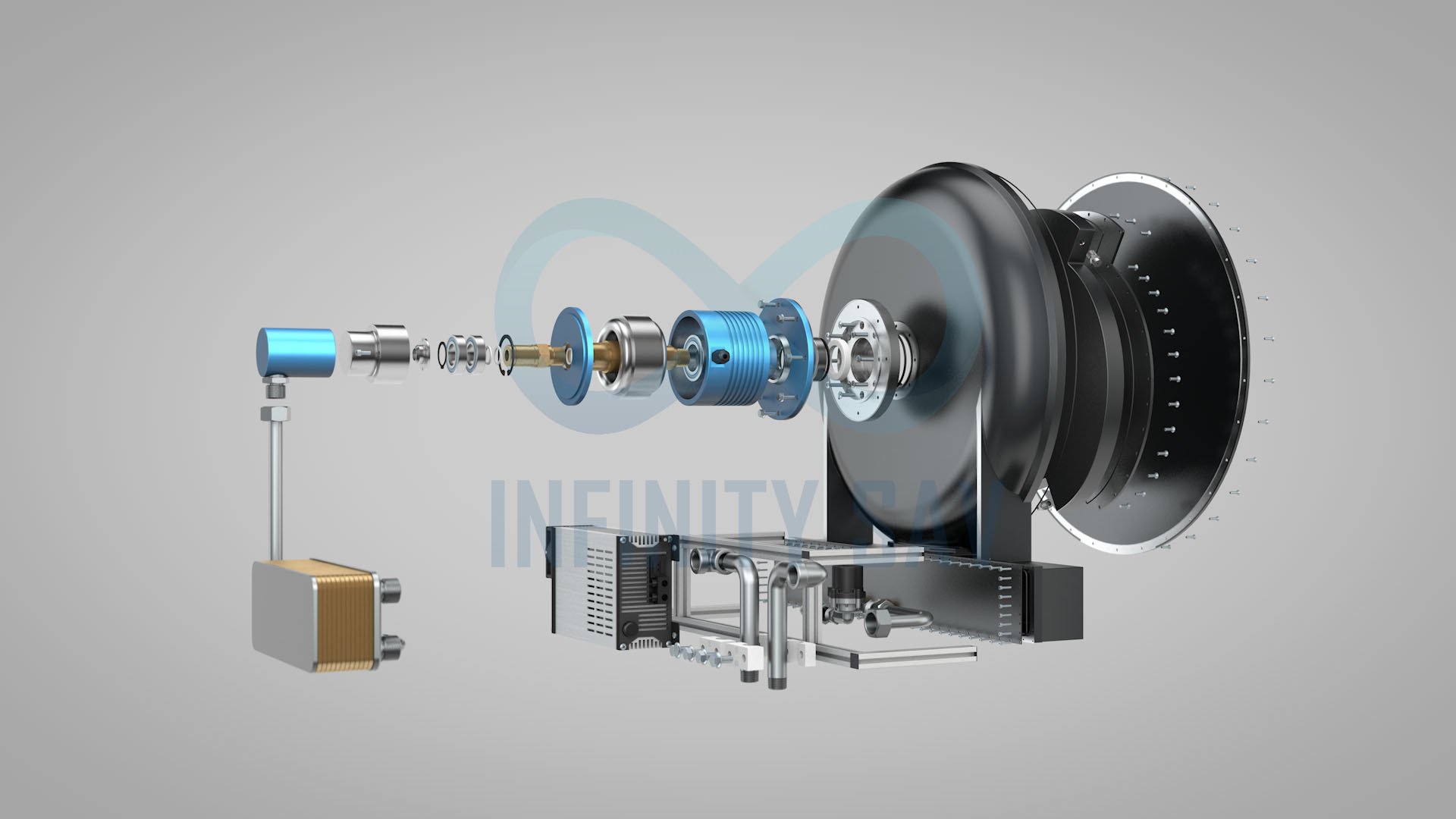

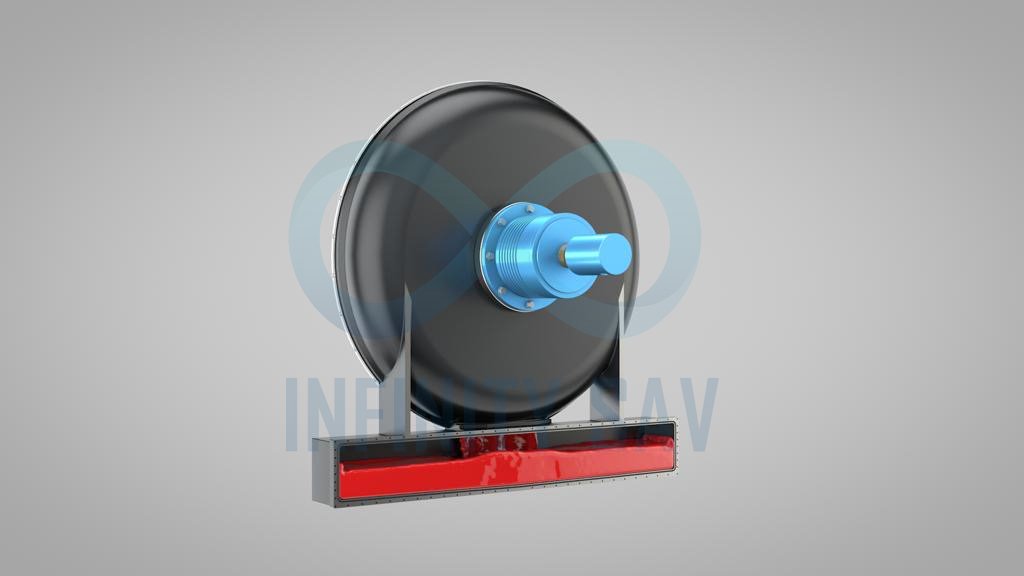

The Centrifugal Boiler iSAV relates to a closed system of oil circulation in which electrical energy supplied to the motor is transformed into mechanical energy of the disk rotation, which in turn is transformed into thermal energy of oil injection. The device utilizes jet propulsion of oil that gets compressed under influence of centrifugal and inertial forces and is spurt out from the disk onto the reflectors, so the thermal energy is generated due to cavitation forces that act on oil passing through nozzles.

The process starts when the motor is activated and reaches 10,000rpm. Since both motor and the disk are installed on the same shaft, the disk also reaches this speed. Next, the oil pump starts pumping oil from the tank and supplies it to the rotary joint, where it is transported through the shaft to the disk.

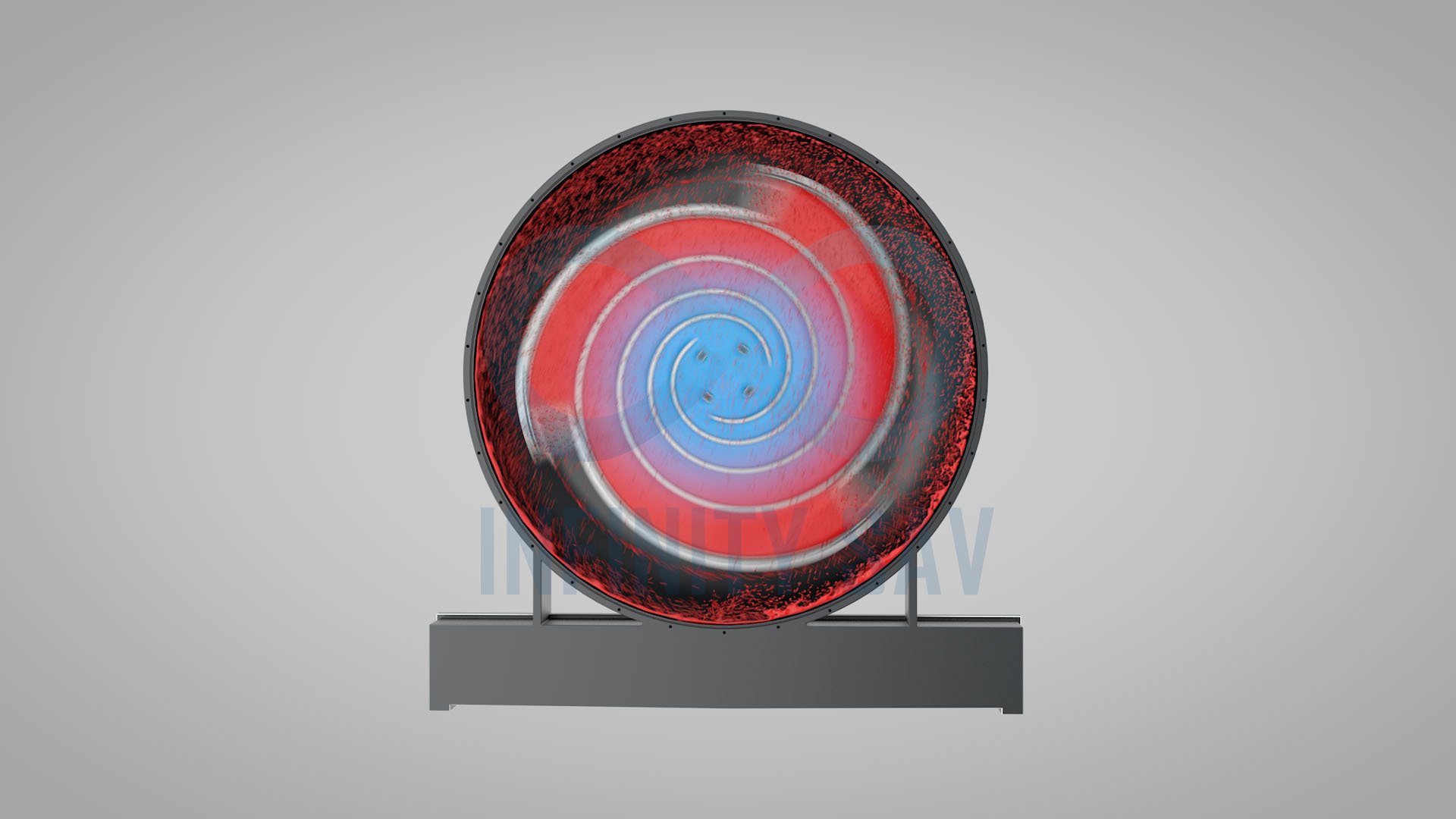

Following the logarithmic spiral shaped structure of the disk, the oil is getting compressed as it reaches three of its edges. The closer oil gets to the edges, the bigger forces are created by oil inside the disk.

Two in particular, centrifugal force and inertial force. Under influence of these forces oil gets compressed.

At each of three edges compressed oil reaches high pressure and gets injected out of the disk through the nozzles and create jet propulsion. Once oil is injected to the deflectors inside the support panel it drains down back to the tank.

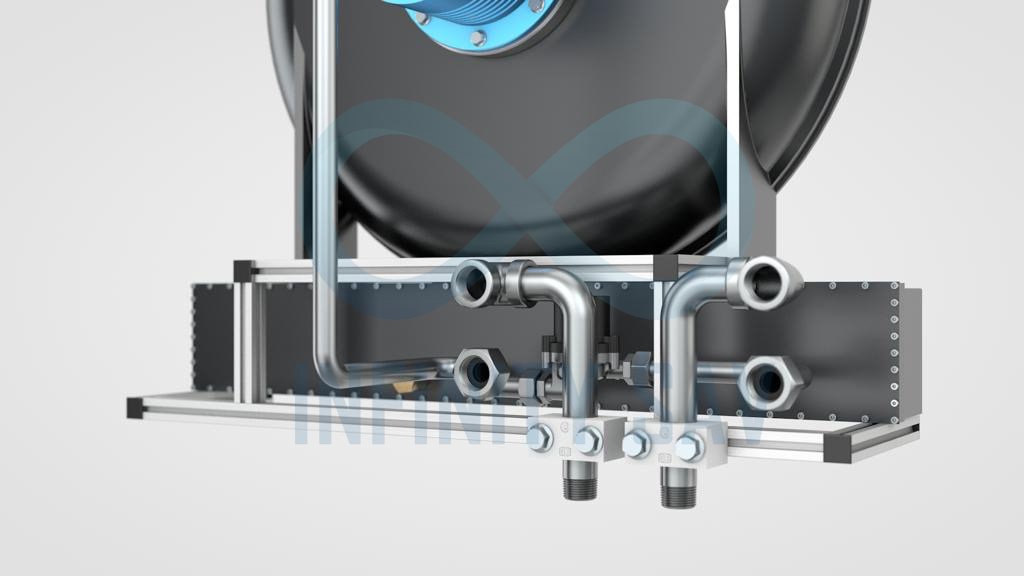

The Centrifugal Boiler iSAV is a water heater which is designed for instant heating. The boiler does not have a storage tank, and the water is heated by a straight circuit. The centrifugal boiler contains a double-circuit plate heat exchanger. Heated oil is circulated through the first circuit, and water that needs to be heated is circulated through the second external circuit. The heat exchanger is made of copper.

Hot oil inside the tank passes between pipes of the flow heat exchanger exchanging temperature with them. Cold water is supplied to the heat exchanger pipe through improved stainless steel pipes that intake thermal energy from hot oil and withdraw warm water at the output. The oil after having given away its thermal energy gets cooled and repeats the cycle over and over again generating more and more thermal energy.