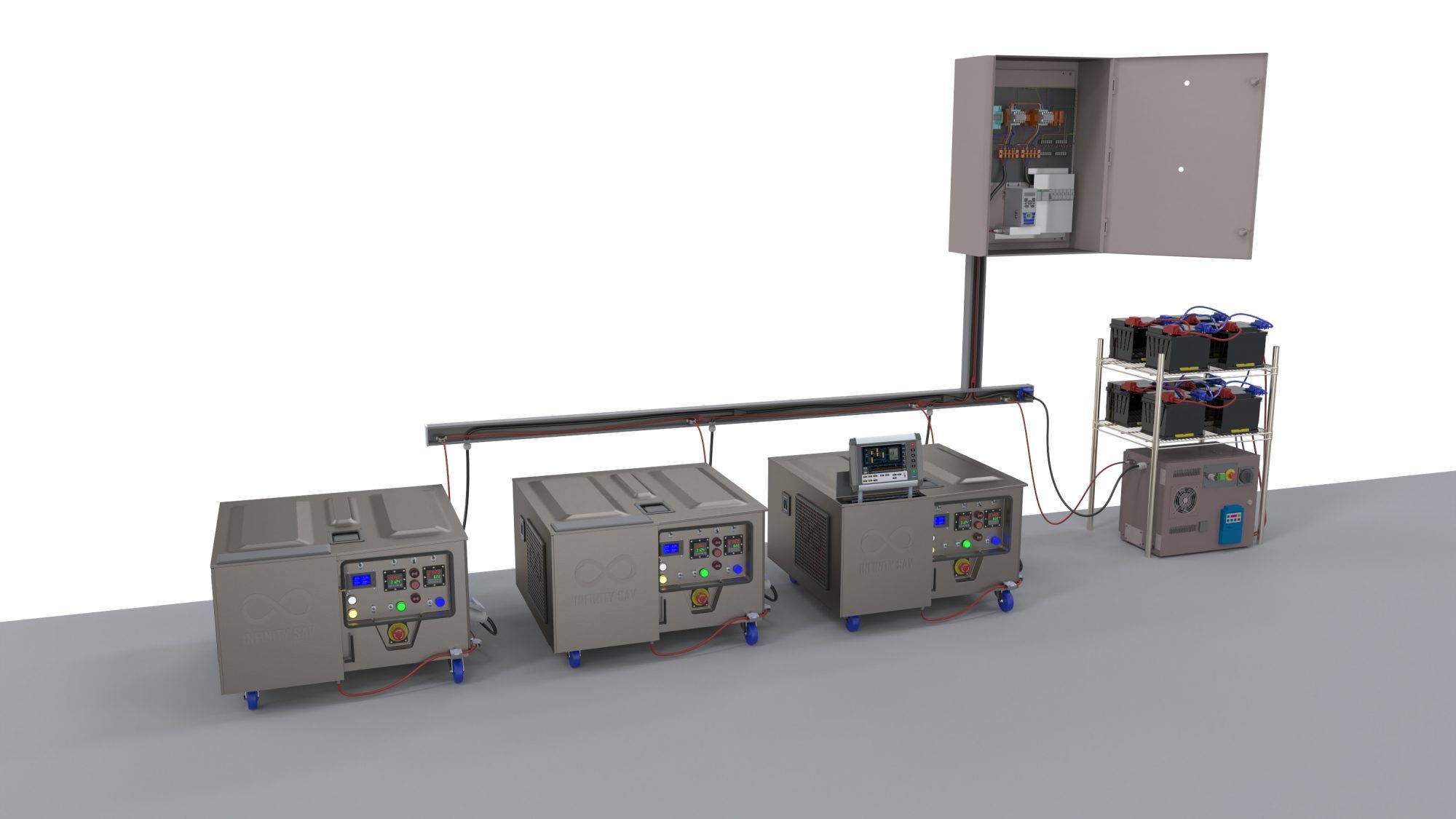

MG10

Abundant Renewable Energy

Without Fuel - 24Hrs / day

DESCRIPTION

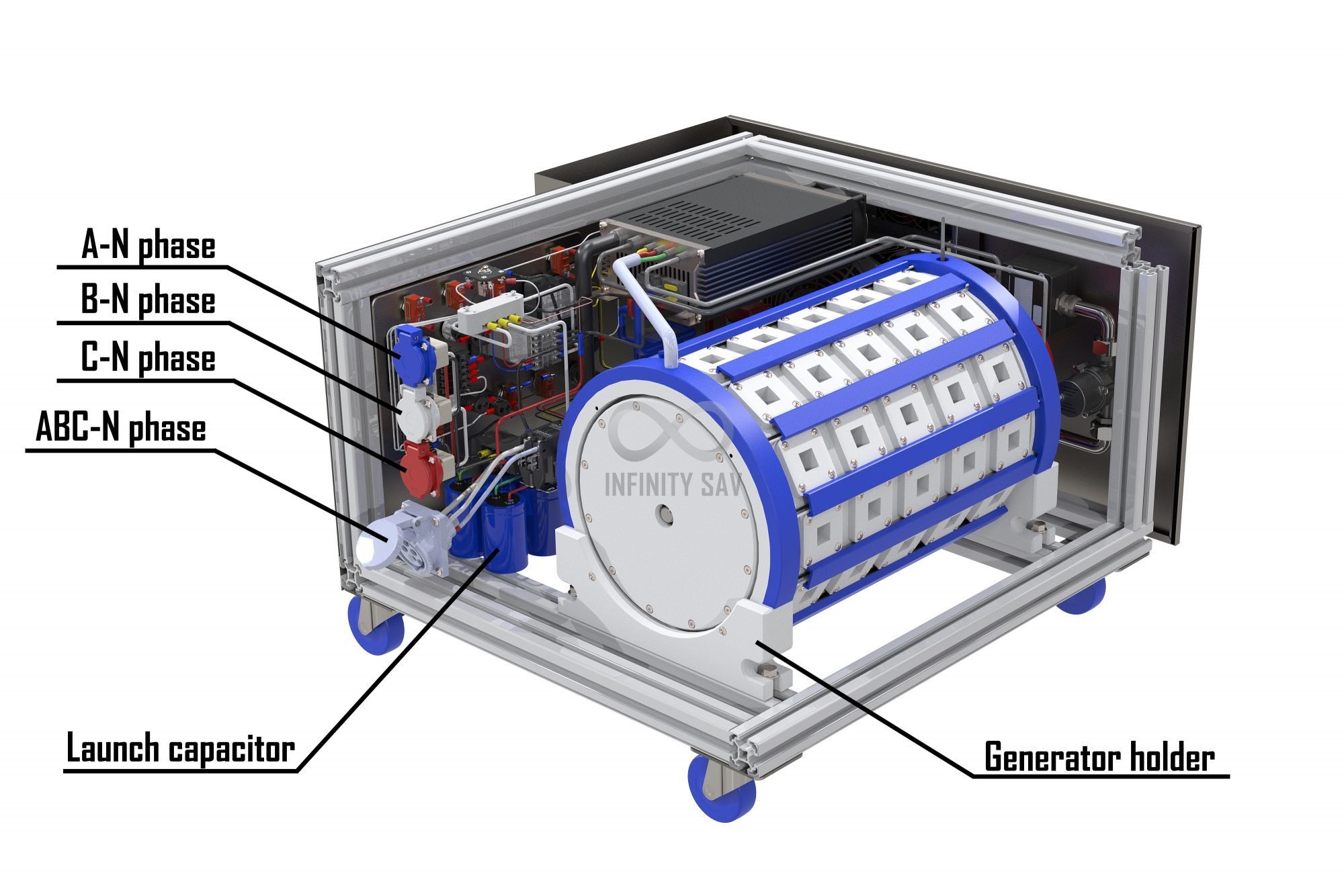

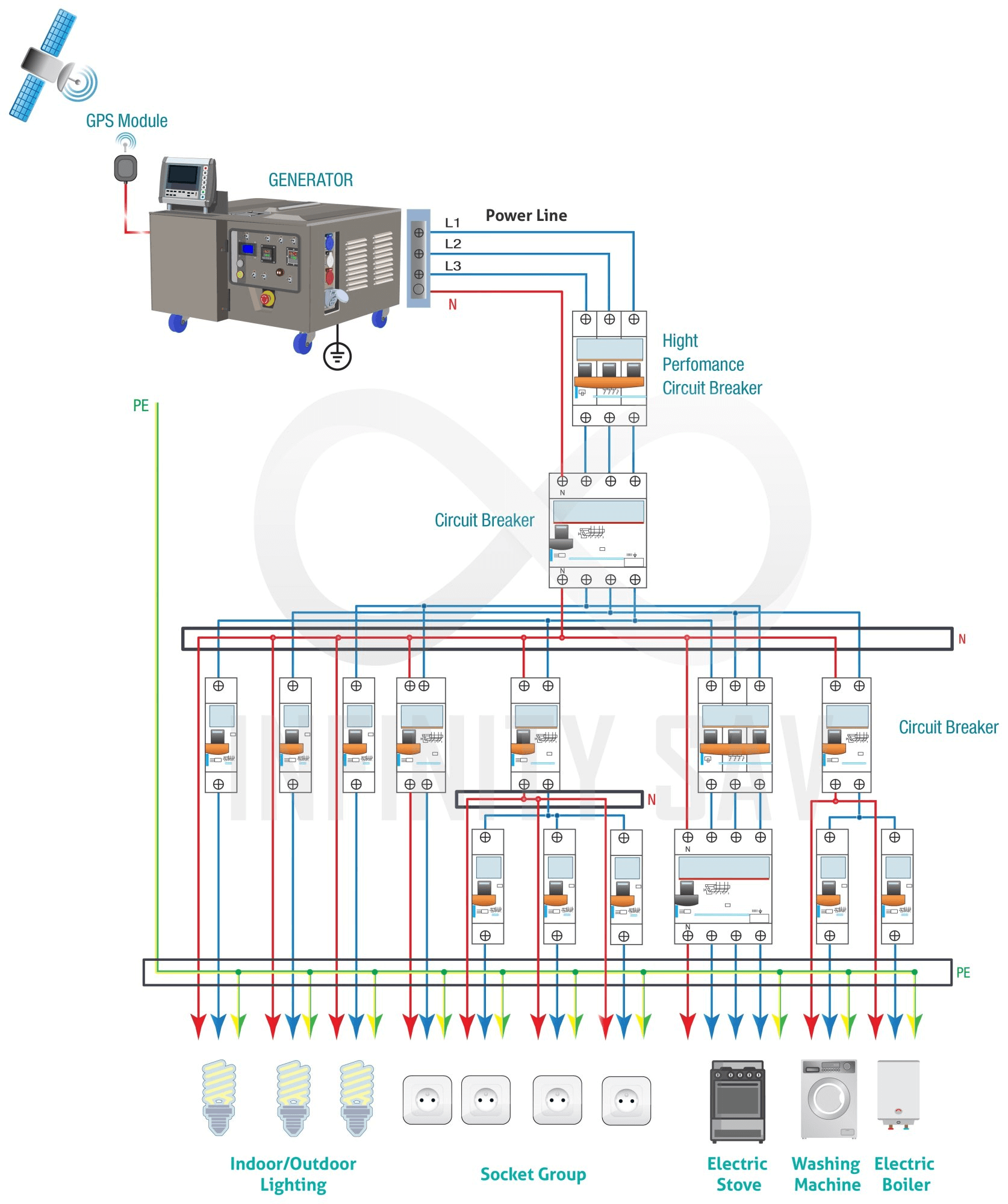

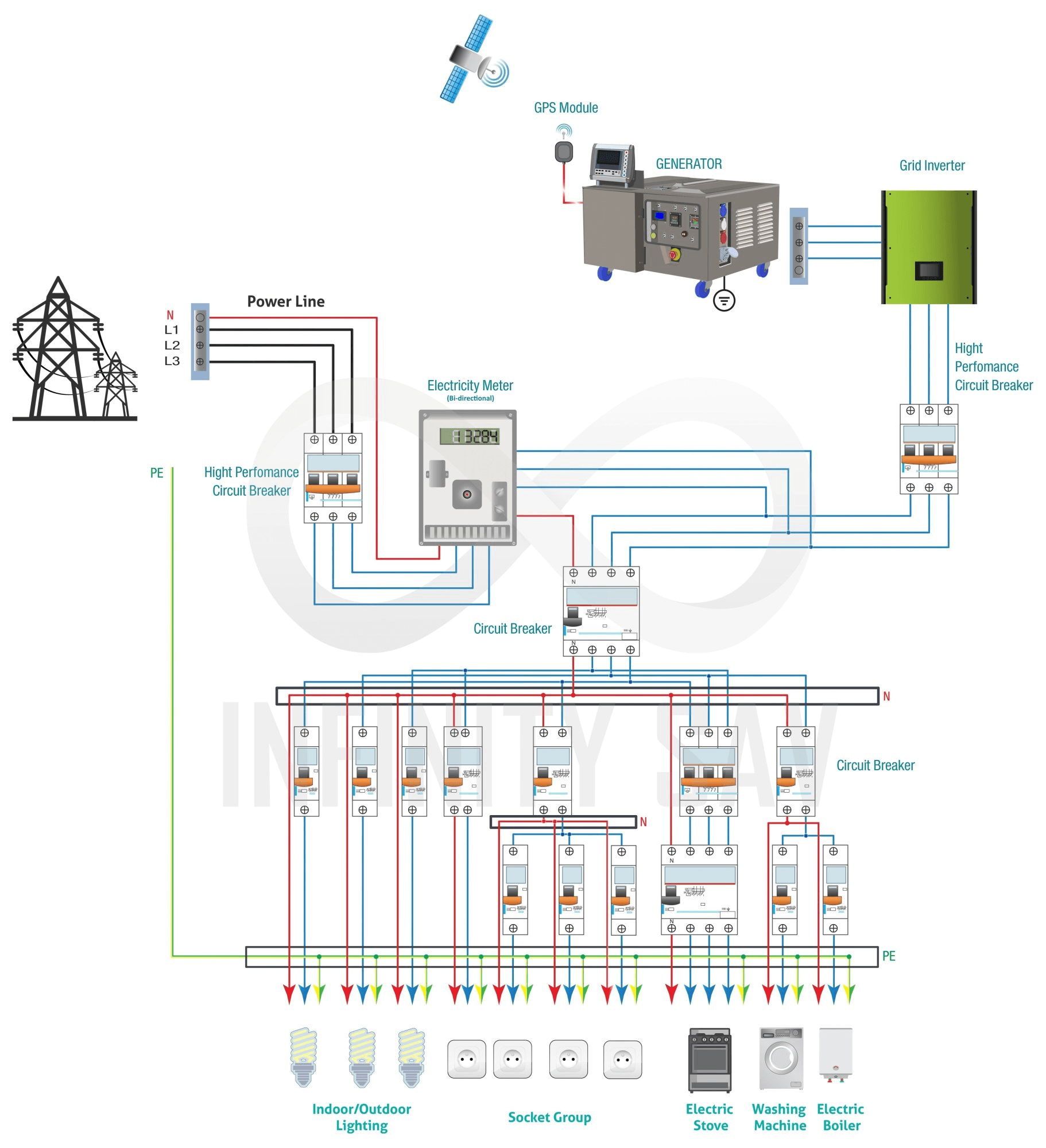

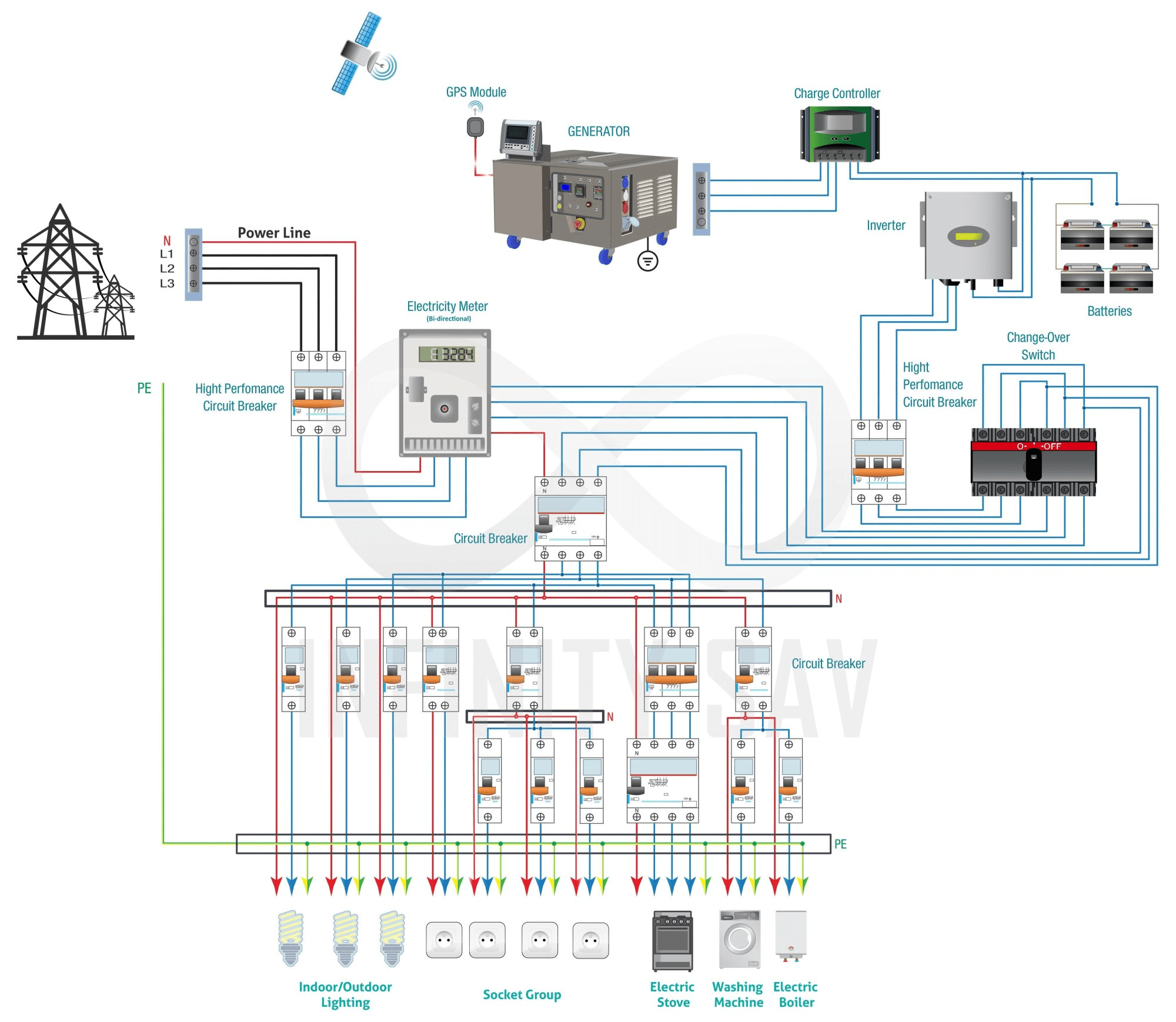

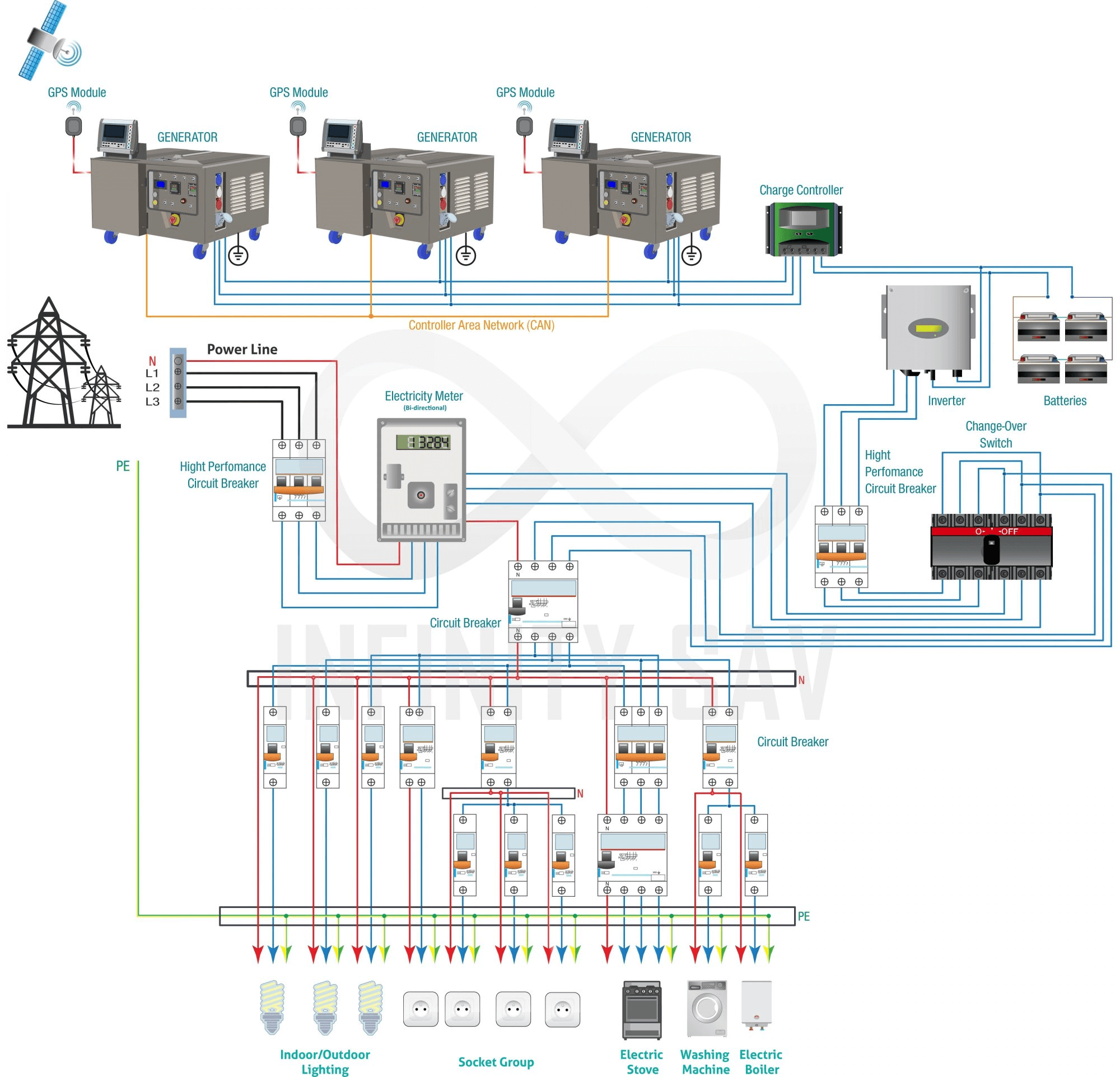

The MG10 supplies up to 10KW of electricity (single or 3 phase) for domestic and commercial applications

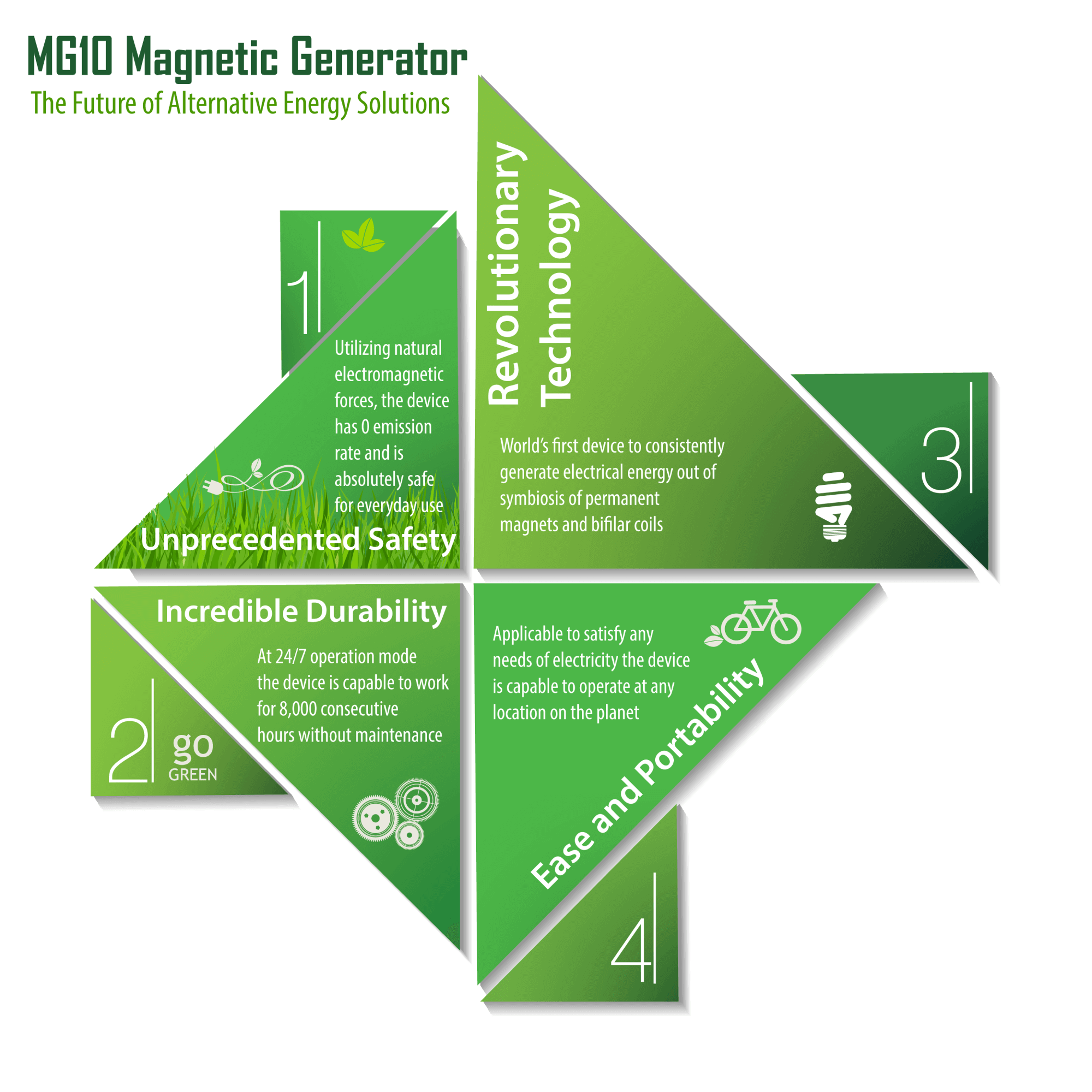

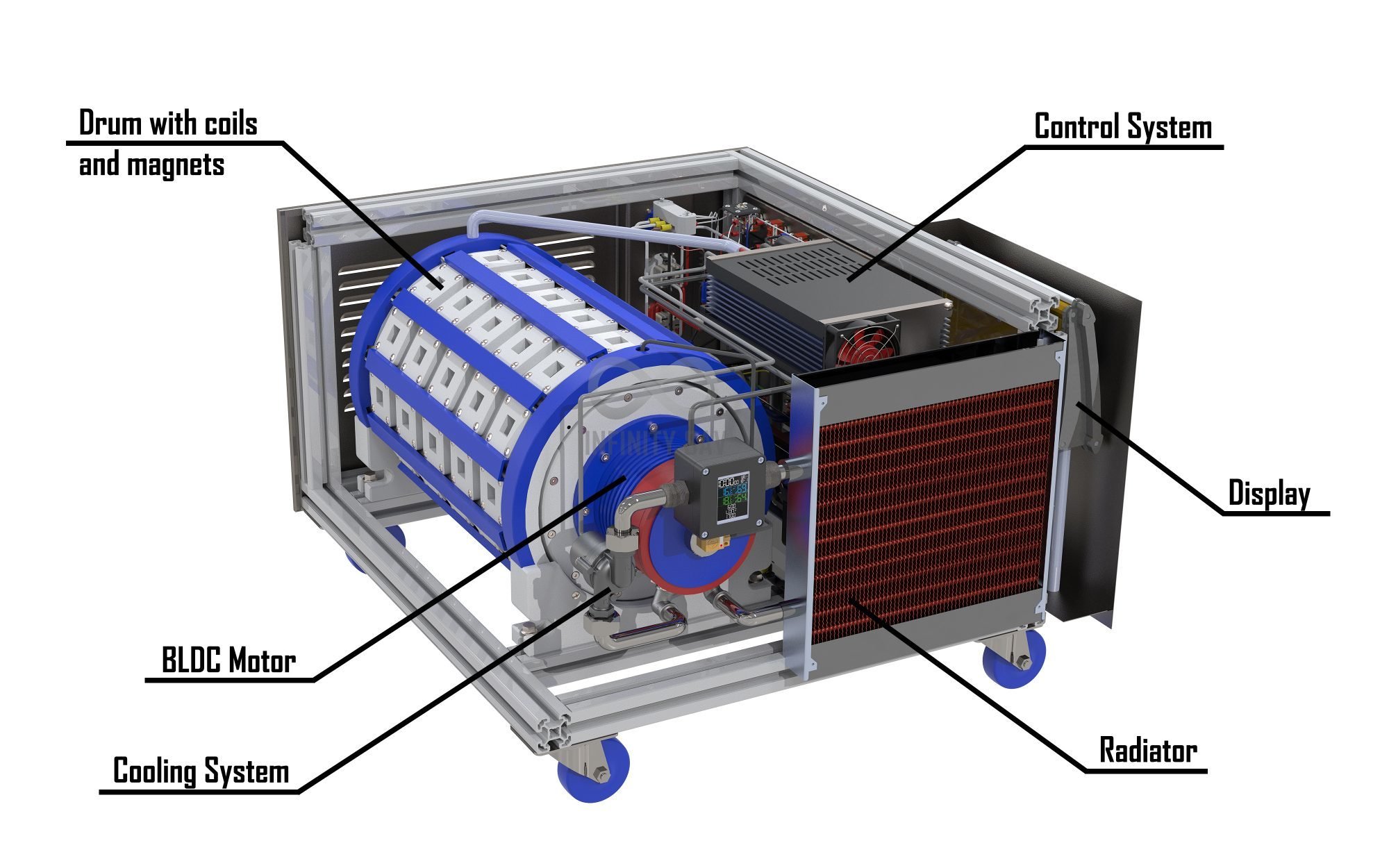

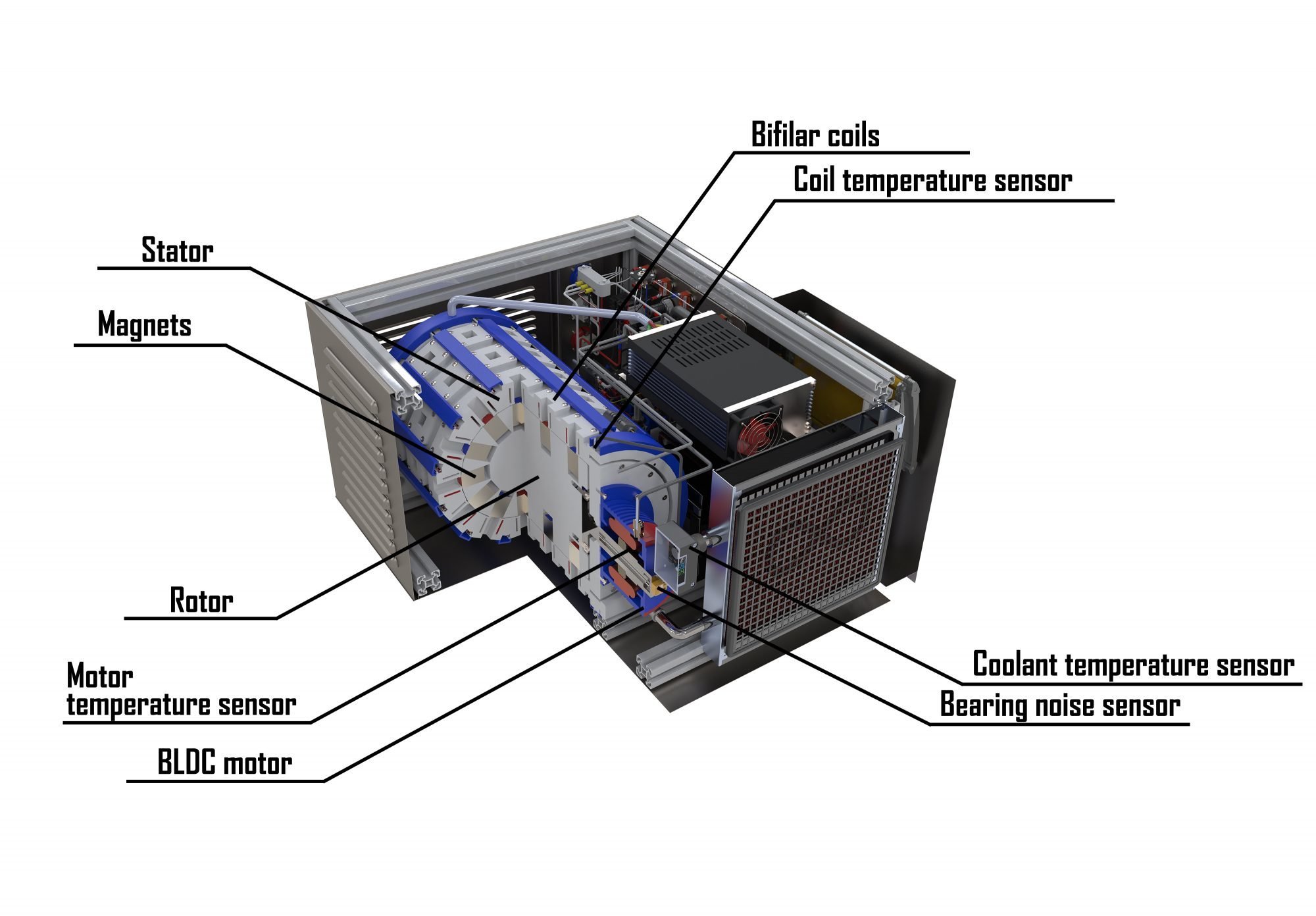

The Magnetic Generator is complex system with an organized structural arrangement of permanent magnets, bifilar coils and PCB controller with specially designed software.

Initial start is performed by a battery or any other external source of energy to help motor reach needed RPM. After start the external source can be disconnected.

The device is able to operate in autonomous mode and maintain its RPM regardless of amount of useful energy being consumed.

Detail theory of operation in FAQ section.

PROTECTION

RPM control sensor

The BLDC motor of the Magnetic Generator is designed to withstand various loads and maintain its RPM regardless of external conditions. It has a build-in RPM control sensor that is used to monitor rotation of the motor shaft and prevent it from deviating from the operational limits (± 5rpm from default). The drum of the generator is driven by the BLDC motor through pulse-width modulation of the software driver in accordance with a specified algorithm. In case of an error of the processing algorithm and deviation from the rotation limits, the RPM control sensor will automatically shut down the whole system as it is an autonomous apparatus and is independent from the algorithm. The generator’s display will present the error and provide solution for it.

Temperature sensors

There are several temperature sensors installed inside the Magnetic Generator. Each sensor is used to measure ambient temperature around generator’s windings and coolant of the device. The generator emits heat insignificantly but the power control circuitry requires monitoring and cooling dependent of environmental conditions and energy load. On detection of temperature rise the cooling system will circulate coolant through the ductwork and run the radiator fan to dispose it outside. In case if temperature of any of the components keeps rising the correspondent sensor will shut down the device and the generator’s display will present an error.

Bearing noise sensors

Maintenance depends on lifecycle of its bearings and other moving components. Being the main source of frictional forces between the motor and its shaft it is crucial that bearings are always greased or replaced when needed. In order to perform maintenance at the right moment, bearing noise sensors are used to detect any significant noise or vibration level deviation from the recommended by the manufacturer limits. When life of a bearing comes to an end or it needs additional grease the sensors will display a message of an upcoming maintenance to the user. If noise generation exceeds maximum limit the sensors will shut down the device to prevent other moving components from damage.

Unauthorized access sensors

The Magnetic Generator is physically protected from an unauthorized access by various methods, one of which is detection of the external case opening. Each side of the generator is equipped with several motion detection sensors which serve to prevent people from opening the device. In case if one of the sensors detects the opening it will automatically shut down the device and will not let it start until an authorized person activates it.

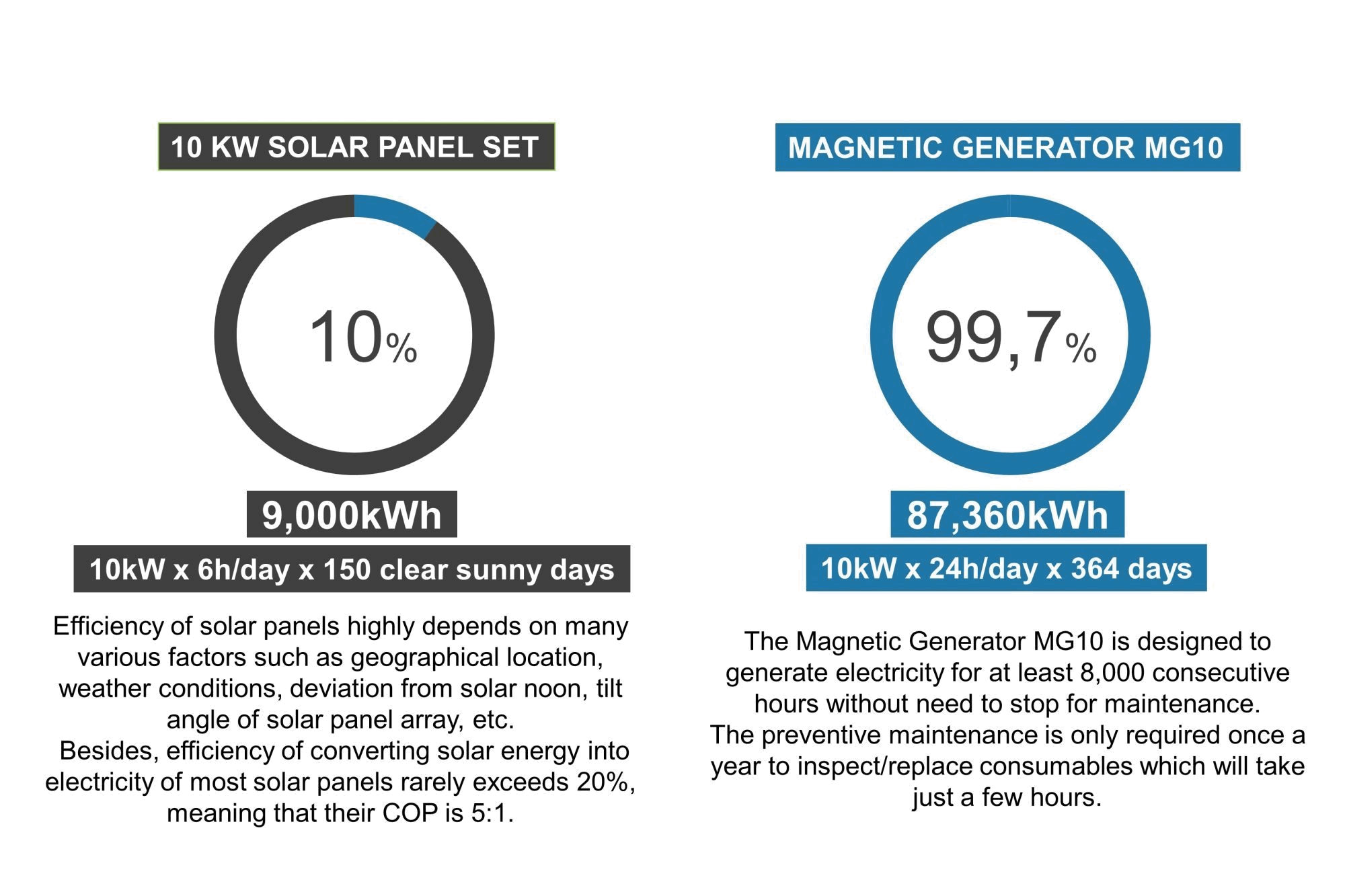

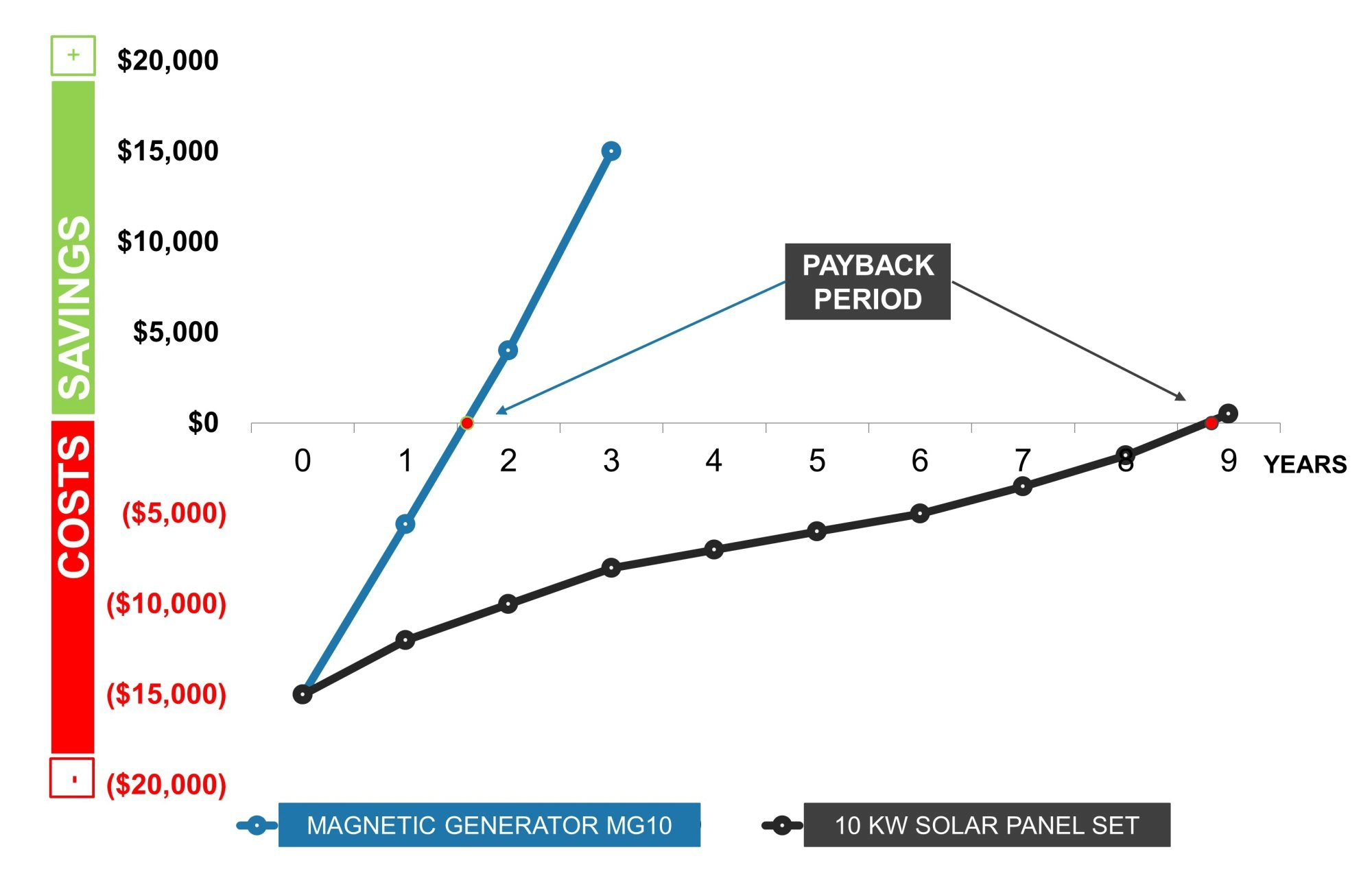

| MAGNETIC GENERATOR MG10Electricity price: 1kW = $0.24 (AU average) Lifespan >20 Years |

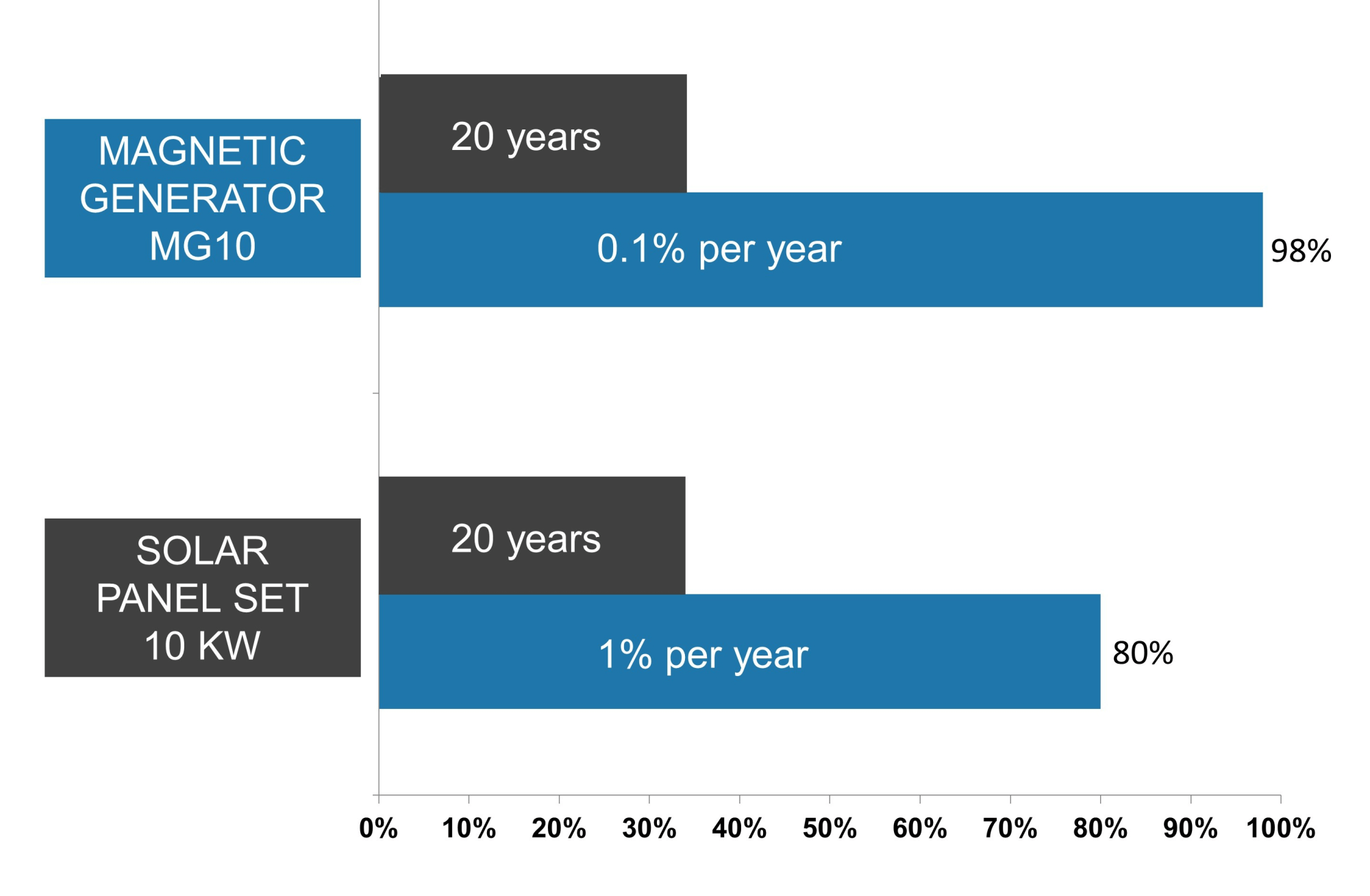

LIFESPAN AND DEGRADATION RATE

| MAGNETIC GENERATOR MG10In the absence of external influences, neodymium magnets remain magnetic for hundreds of years. Demagnetization of generator’s magnets is extremely small if the device is used properly with a rate of 1% every 10 years. If maintenance is performed regularly and duly, the generator may serve indefinitely longer than its 20 year lifespan. SOLAR PANEL SET 10KWPhotovoltaic (PV) modules of solar panels manufactured today offer a much longer lifespan of 20 years of use. However, degradation of crystalline silicon modules located in extreme climates (heavy wind, snow load, high levels of UV exposure) exhibits high rates of approximately 1% per year which leads to 20% of efficiency loss at the end of solar panel lifespan. |

|  |  |

Infinity MG10 | |

|---|---|

| Total capacity | 13050W |

| Control system consumption | 50W |

| Motor consumption | Idle – 200W, full load – 3KW |

| Generated voltage | 900 AC |

| Generated frequency | 400Hz |

| Generated current | 11.2A |

| Effective power output | 10KW |

| Effective frequency output | 50/60Hz |

| Effective voltage output | 110V / 1 phase / 100A 220-230V / 1 phase / 50A 220-230V / 3 phase / 16A 380-440V / 3 phase / 16A |

| Motor rotation | 1500 rpm |

| Dimensions | 750x715x528 |

| Weight | 80 kg 80 kg |

| Noise generation | 60dB |

| Operation temperature range | -40°C ~ 70°C |

|  |

|  |